Green Efficiency

At Piab Group, we are committed to being a catalyst in the fight against climate change. By leveraging our expertise in developing cutting-edge products and solutions, we enable new levels of resource efficiency. But our commitment goes beyond product innovation. We are also dedicated to running a CO₂-neutral business by reducing our energy consumption and contributing to a circular economy. Through these efforts, we believe we can pave the way toward a more sustainable future, demonstrating that environmental responsibility and business progress can go hand in hand.

Scope 1

Our car fleet accounts for 76% of our Scope 1 CO₂ emissions. We are proudly dedicated to ecological responsibility and have committed to making our entire vehicle fleet 100% electric by 2030, supporting our journey toward a more sustainable future.

Scope 2

Most Scope 2 emissions come from electricity used at our offices and manufacturing sites worldwide. We are transitioning to renewable electricity from grid, solar, and wind sources. Today, nearly 50% of our electricity comes from renewable sources.

Scope 3

Our Scope 3 emissions come from three main categories: upstream transportation, use of sold products, and purchased goods & services. We are fully committed to continuous improvement, benefiting not just Piab but everyone in our value chain.

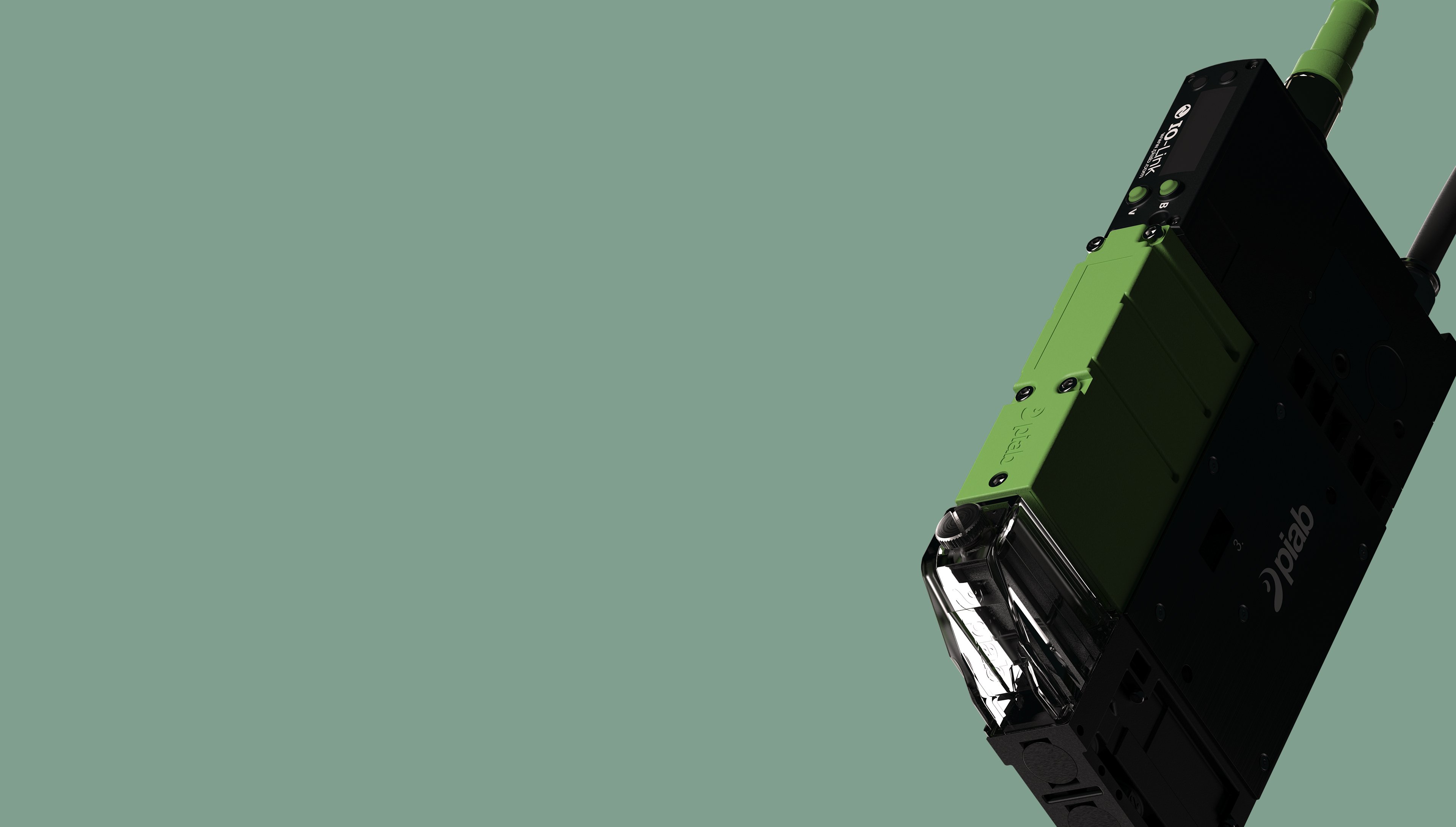

Energy saving functionality

Objectives for vacuum generation and release

- Reduce energy consumption by up to 95%, the ability to pick and place objects with the same gripping power using significantly lower energy consumption, equal to a saving of 50-100 tCO₂e*

- Autonomously Optimizing vacuum generation: Dynamically adjusting the capacity of the vacuum system to the application needs to reduce the energy consumption to a bare minimum

- Minimizing energy usage for object release: Use innovative release technologies to minimize energy consumption

- We´re designing vacuum gripping systems optimized to max the gripping power and minimize the energy waste

*Automotive body-shop in the US, 2024

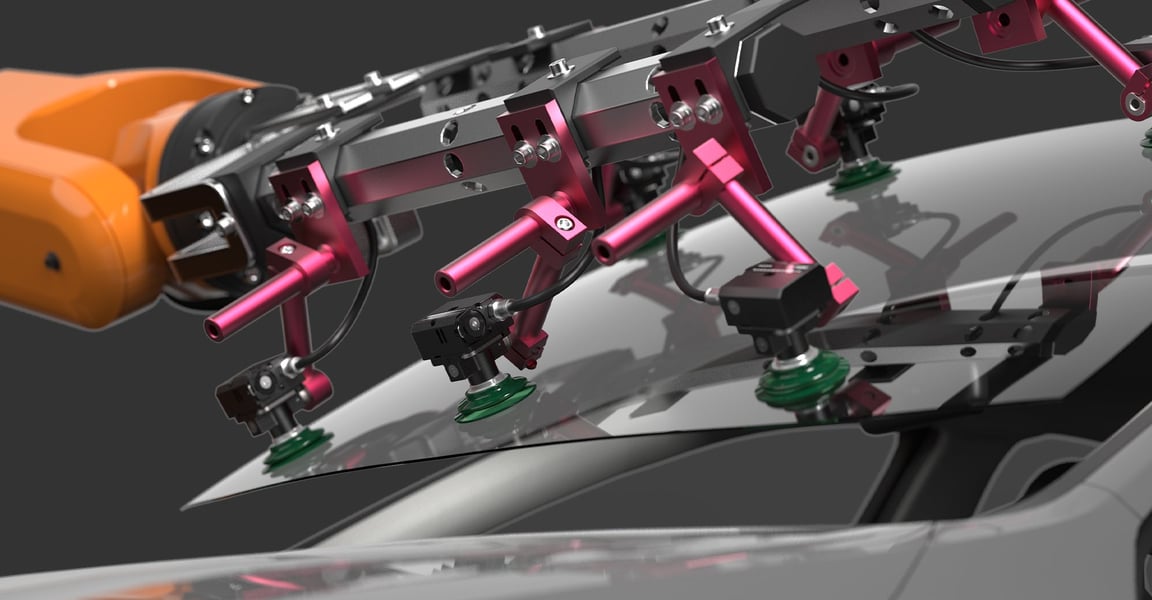

Aluminum gantry system

Reduced CO₂ emissions with new aluminum gantry system

- 10-20% lighter profiles can reduce CO₂ emissions by 35 tons/year

- Stronger joint reduces scrap, leading to 19 tons/year in reduced CO₂ emissions

- Energy savings in manufacturing up to 40,000 kWh (no oven heating), plus 25,000 kWh (no cleaning system)

- Up to 20% faster installation due to no onsite drilling

Designed for circularity

Objectives for using a single material filter for improved circularity

- The all-new filter is crafted from recyclable polyethylene, using less material than our current range of filters, and consequently emits less CO₂

- Constructed from a single material, the filter is easily managed as waste

- It ensures maximum performance throughout its lifetime and can be washed repeatedly

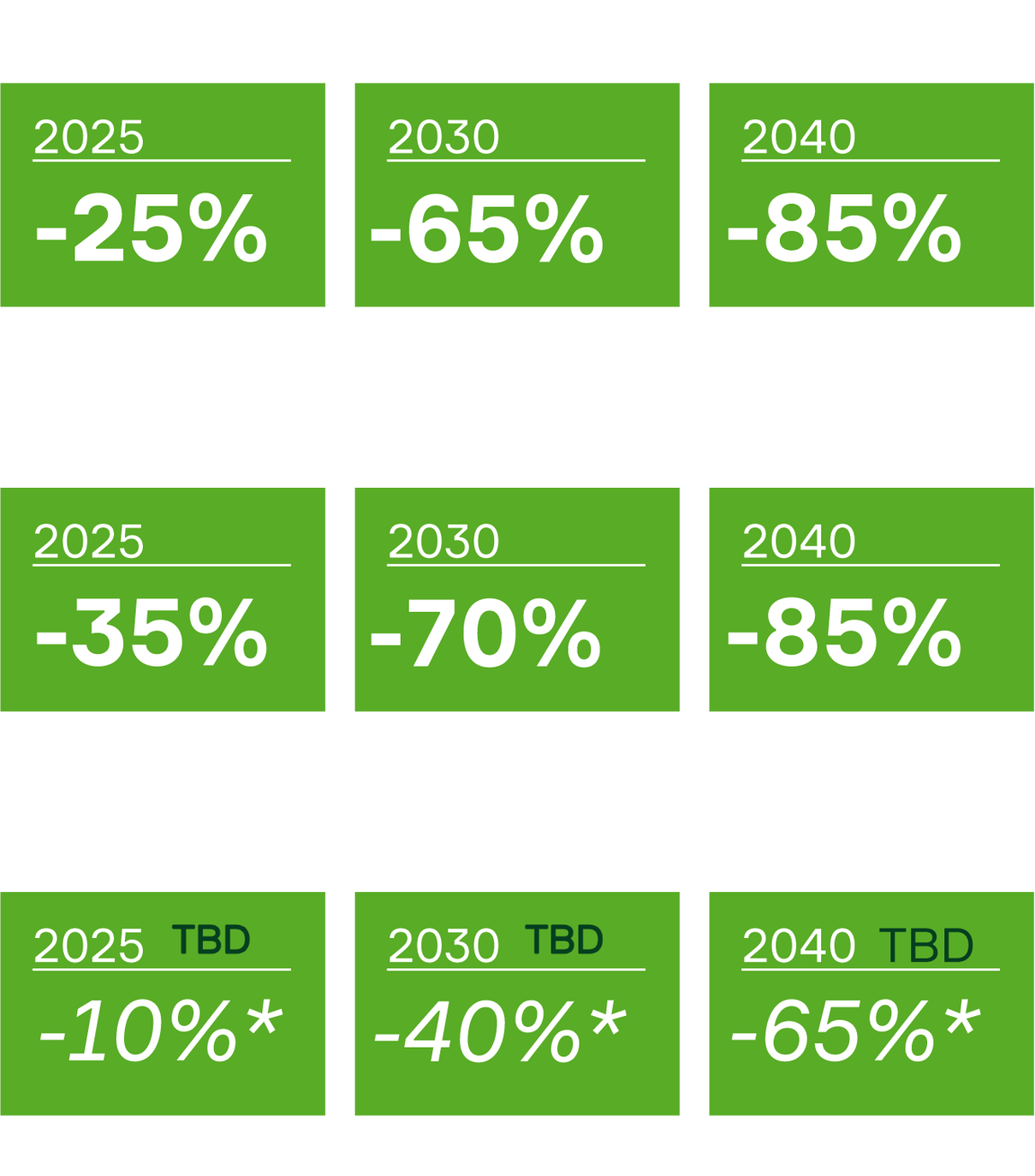

Piab Group CO₂-emission reduction targets

Three scopes are used to categorize a company’s direct, indirect and other associated carbon emissions. Within each scope, Piab Group performs regular assessments to define relevant reduction targets and measure our progress towards achieving them.